PRT PowerSleeve® is our Field-Wetted 100% solids epoxy, engineered composite system. In the PRT design process it is used to encapsulate internal corrosion and act as a barrier against future through wall conditions in piping repairs. It also provides substantial hoop and axial strength reinforcement properties.

PRT PowerSleeve® consists of a high strength E-glass and Kevlar® hybrid fabric. It is a tri-axial, non-crimped design that is factory pre-treated to assure absolute micro-fiber matrix saturation. Alternate custom fiber alloys and carbon fiber are available for special applications.

PRT PowerSleeve® engineered composite systems combine our hybrid fabric with a PowerMatrix™ 100% solids, impermeable epoxy matrix. In addition to our high performance Standard Matrix, the PowerMatrix™ line has differing formulations for specific high heat requirements and chemical resistance applications.

PRT PowerSleeve is effective in a variety of applications. In addition to piping encapsulations, it is ideal for layups on complex, curved and irregular surfaces due to its conformability. Also, because of the exceptional adhesion properties of the PowerMatrix™ epoxy, it is highly effective for containment and reinforcement of flat surface repairs.

PRT PowerSleeve® kits are size specific packages for pipe diameters ranging from 6 inches to 108 inches. Each kit ships with the precise, factory measured fiber reinforcement and PowerMatrix™ quantities for the repair of a specified pipe diameter. This factory pre-measuring system eliminates field installation errors and assures proper saturation levels. Complete installation supplies such as primer, stricture banding, spreader, gloves, safety glasses, mixing sticks, brushes and UV protective paint for final topcoat are also included in the kits. Because of these controls and preparations, PRT PowerSleeve® installations are efficient and trouble free.

What kind of pipes?

- Aluminum

- Cast iron

- Copper

- GRE

- Stainless steel

- Carbon steel

- Concrete

- Fiberglass

- PVC

- Titanium

Characteristics of the Standard Matrix System

- Chemical Resistance – acetone, mek, toluene, gasoline, ethyl alcohol and many others

- Tensile Strength – up to 70,893 psi, C-2

- Interlaminar Shear – 4,860 psi

- Compressive Strength – 29,500 psi

- Tensile Modulus (e-6psi) – 5.48

- Working Time – 30 min pot life, 1 hour layup

- Cure Time – 8 hours @ 77° F

- Operating temperature 265° F

| PowerSleeve® Type W-11 Standard Resin | PowerSleeve® Type C-2 Carbon Fiber Standard Resin | |

|---|---|---|

| Reinforcement | Stitched tri-axial Kevlar/glass hybrid | Stitched bi-axial Carbon Fiber Fabric |

| Dry Fabric Weight, (oz./sq. yd.) | 22 | 18 |

| Nominal Thickness (mils) | 34 | 44 |

| Tensile Strength (psi) | 58,088 | 70,893 |

| Tensile Modulus (e-6 psi) | 2.73 | 5.48 |

| Tensile Load per ply (pounds) | 1,900 | 2,394 |

| Compressive Strength (psi) | 29,400 | 29,500 |

| Interlaminar Shear (psi) | 4,580 | 4,860 |

| Alternate PowerMatrix™ Properties | Standard System | 70079 System | 439 System | 439-S System | X-TEMP-2™ System |

|---|---|---|---|---|---|

| General Characteristics | The “standard” system. For general use in mild air temperatures onto clean, dry surfaces. | Low temperature system featuring excellent chemical resistance. | Medium temperature system that has slightly better chemical resistance and will post-cure heat treat to a very high Tg. | The slow-cure version of the 439 System. Use where a longer cure time is desired. | High temperature system. For use in applications with constant high working temperatures |

| Gel time in pot @ 77° F | 25 minutes | 30 minutes | 30-40 minutes | 12 hours | 12 hours |

| Working time after fabric saturation @ 77°F | 30-40 minutes | 1 hour | 90 min | 12 hours | 12 hours |

| Dry time after layup @ 77°F | 30-60 minutes | 8 hours | 90 min @150°F | 90 min @ minimum temperature of150°F | 6 hours @ minimum temperature of 150°F |

| Installation temp. range | 45°F – 130°F | 55°F – 100°F | 65°F – 135°F | 150°F – 220°F | 150°F – 220°F |

| Operating temp. range | -40°F – 220°F | -40°F – 140°F | 0°F – 325°F | 32°F – 325°F | 150°F – 450°F |

Temperature Adjusted Pot Life and Set Times Half or Double for Each 10°C Change

| TEMPERATURE | POT LIFE | SET TIME (layup) |

|---|---|---|

| 45°C (113°F) | 7.5 minutes | 1 hour |

| 35°C (95°F) | 15 minutes | 2 hours |

| 25°C (77°F) | 30 minutes | 4 hours |

| 15°C (59°F) | 60 minutes | 8 hours |

| 5°C (41°F) | 120 minutes | 16 hours |

What Types of Repairs?

- Abrasion / wear resistance

- Bend repairs

- Corrosion mitigation

- Cracks

- Dents / gouges

- Encapsulation

- Full hoop / axial strength replacement

- Isolation / Insulation

- Leak repair (special applications)

- Manufacturing / fabrication defects

- Structural reinforcement

- Weld joint/HAZ reinforcement

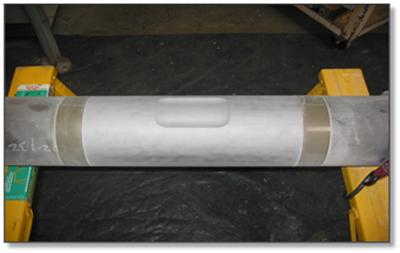

Pressure testing of a repaired pipe section pursuant to the “Short Term Spool Test” in appendix III of ASME PCC-2.

- 6″ X42 80% Wall Loss Machined Defect 6.625” x 3.125”

- Tested to 8200 psi With No Failure per ASME PCC-2

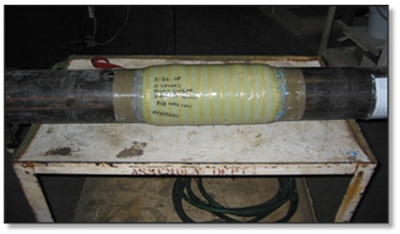

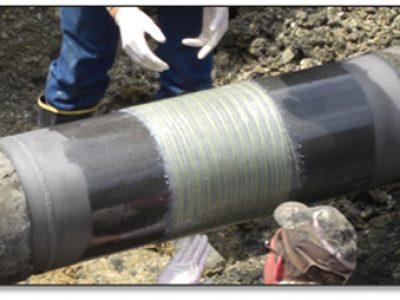

PRT PowerSleeve® Installation

- A. 12” Natural Gas / Internal Corrosion / NACE II Media Blast Preparation

- B. Primed Repair Area with PRT PowerSleeve® Epoxy

- C. Field Wetting E-Glass / Kevlar® Hybrid Fabric with 100% Solids Epoxy

- D. Installing First Layer of PRT PowerSleeve® Composite

- E. Installing Final Layers of Composite Wrap

- F. Completing Installation by Securing with Stricture Banding During Cure